The grinding wheel as a tool which works on the basis of metal cutting consists of the components grinding material – normal corundum, precious corundum red or white, silicon-carbide – and bonding material (vitrified, bakelite, rubber). The abrasive grain removes material from the workpiece. The function of the bonding is releasing the dull grain on time.

The following abrasive materials are used:

APEX-CORAP-normal corundum (NK): colour brown-blue-grey

APEX-CORAP-extra precious corundum (EK): colour red or white

APEX-SILAP-silicon-carbide (SC): colour green

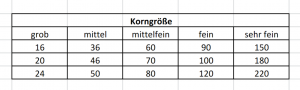

The above mentioned abrasive materials are available in the desired micrograph according to different grit sizes. The grit size is an international standardisation of mesh size after filtering. Bigger mesh mean coarse grain, smaller mesh mean finer grain. The grit sizes are divided into:

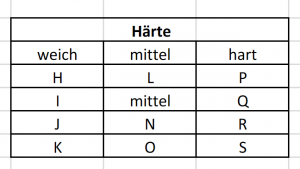

The hardness of the grinding wheel is caused by the resistance of the bond against break-out of the abrasive grain during sharpening operations. Due to the application there is a soft, medium or hard embedding of the abrasive grain possible into the grinding wheels. The classification is due to the common hardness scale:

The standard diameter of ceramic grinding wheels indicated in mm:

100 – 125 – 150 – 175 – 200 – 225 – 250 – 300 – 350 – 400

The standard width indicated in mm:

6 – 8 – 10 – 13 – 16 – 20 – 22 – 25 – 32 – 40 – 45 – 50

——————————